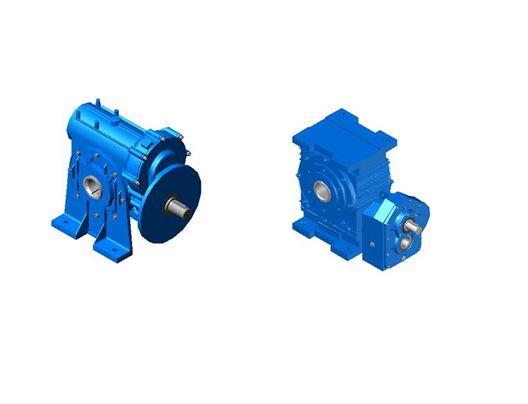

Gearboxes, also known as gear drives, are the arrangement of their shafts or the way that they mount to the driven equipment. However, it is important to realize that shaft arrangement and mounting are two different characteristics of the drive.

Therefore, it is important to know both aspects to successfully determine the best gearbox for your application. The shaft arrangement on a gear drive is the location of the high-speed and low-speed shaft extensions relative to each other.

This is dictated by the position of the motor and driven equipment and is sometimes constrained by the physical space of the application. The orientation of high and low-speed shafts as they relate to the naming of the different types of gear drives may seem very simple, but there are reasons why you would choose one over the others when determining the best gearbox for your application.

The primary determinant for selecting the type of gearbox is space limitations in a system. Because the shafts are oriented differently, your driving equipment, or motor, will be in a different location depending on which type of gear drive is selected.

Benefits & Uses:

| Industries | Applications |

| Agriculture | Heavy duty bulk material handling |

| Automotive | Heavy duty process specific |

| Cement | Water treatment |

| Energy | Aggregate & construction equipment |

| Forest | Grain handling |

| Mining | |

| Cement & Aggregate | Light to medium duty conveying |

| Sand-Gravel | Belt conveyors |

| Mining | Classifiers |

| Grain | Separators |

| Baggage/Package Handling | |

| Pic-Pac-Retrieval | |

| Energy | |

| Metal Processing | |

| Agriculture | Conveying |

| Automotive | Reclaimers/stackers |

| Cement & Aggregate | Crushers |

| Energy | Mills |

| Mining | Feeders |

| Pumps | |

| Dryers | |

| Mixers/blenders | |

| Agitators | |

| Loaders/unloaders | |

| Elevators | |

| Agriculture | Conveying |

| Food & Beverage | Reclaimers/stackers |

| Cement | Crushers |

| Forest | Mills |

| Mining | Feeders |

| Pumps | |

| Dryers | |

| Mixers/blenders | |

| Agitators | |

| Loaders/unloaders | |

| Elevators |