Speed Variations:By feeding fixed speed to Variator, steeples speed variation can be obtained from

- Max. Speed = 1.7 x Input speed to

- Min. Speed = 1/7 x input speed

- Max.Speed/Min.Speed = 12:1 to 3:1 depending upon selection

_________________________________________________________________

Torque Multiplier:

When speed is reduced, Variators can replace Gear Boxes.

_________________________________________________________________

Speed Multiplier:

Up to 1.7 times input speed without necessity of speed increasing gear.

_________________________________________________________________

High Output Torque – Over Load Capacity:

Up to the standstill of an electric motor of the same power acting as a mechanical clutch.

_________________________________________________________________

High Efficiency:

Overall 85% throughout full speed range ideally used for constant power transmission applications in all types of Industries.

__________________________________________________________________

Speed Holding:

Quite stable with uniform load and within 0.25% with Max. Load.

__________________________________________________________________

Reliability:

Drive is highly reliable with long life as load is equally distributed on number of conical Rollers, which are hardened, and ground to close tolerance.

__________________________________________________________________

Simple Design:

Can be attended by skilled fitter as no electronic/electrical parts/circuits are involved.

__________________________________________________________________

Compactness:

High Power Transmission capacity with small dimensions.

__________________________________________________________________

Speed Control:

Quick and simple. By rotating control knob in running condition only.

__________________________________________________________________

Free From Noise And Vibrations:

No moving parts like Chins, Belts, etc. Drive is through rolling action of PRECISION ROLLERS, which are continuously lubricated. All components are well balanced.

__________________________________________________________________

Bi-directional Rotation Of Output Shaft:

Clockwise/Anti Clockwise depending upon Input shaft rotation, viz. Anti Clockwise/Clockwise respectively.

__________________________________________________________________

Totally Enclosed Unit:

Ideal for hazardous zones.

__________________________________________________________________

Maintenance:

Practically maintenance free. Only ensure proper lubrication.

__________________________________________________________________

Collinear Input & Output Shaft:

In-Line Input and Output Shafts.

__________________________________________________________________

Before Selecting the Variator Consider Following:

Load Factors:

- Uniform load: 1

- Medium shock load: 1.5

- Heavy shock load: 2

Service factors:

- 8 Hours running – 1

- 16 Hours running – 1.25

- 24 Hours running – 1.5

Efficiencies of various driving elements used in drive system.

For frequent start/stop, reversal operation, and high moment of inertia load consult us

____________________________________________________________________

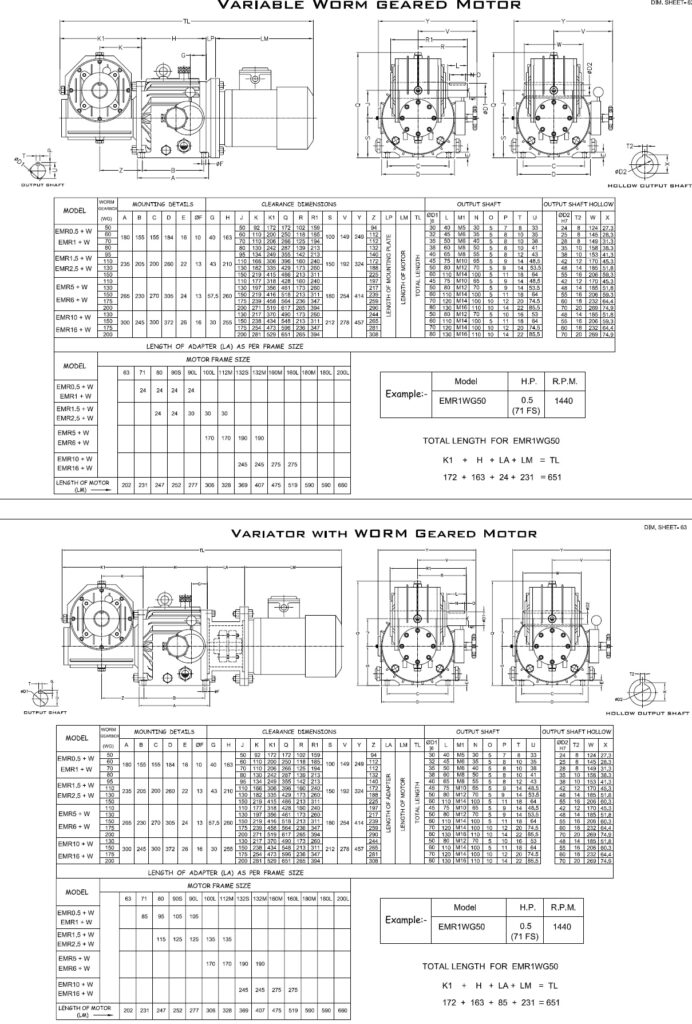

For Further Reduction Use At The Output Shaft Of The Variator:

- Chain drive (positive)

- Belt drive (slip occurs) For reduction up to 4:1

- Suitable reduction gear boxes (worm/helical) by Elmrad